Design & Prototyping

Over our 20+ year history we have designed and manufactured not only our own product ranges but helped develop products for other companies too. We can work from an initial idea or reverse engineer (using 3D scanning or our FARO arm) an existing part or product be it a single component or assembly. We can also take CAD files and discuss project requirements.

We can provide full linear or non-linear, static or dynamic FMEA structural composite optimisation can be quoted if required or we can provide laminate specifications suggestions for your test and verification based on our experience.

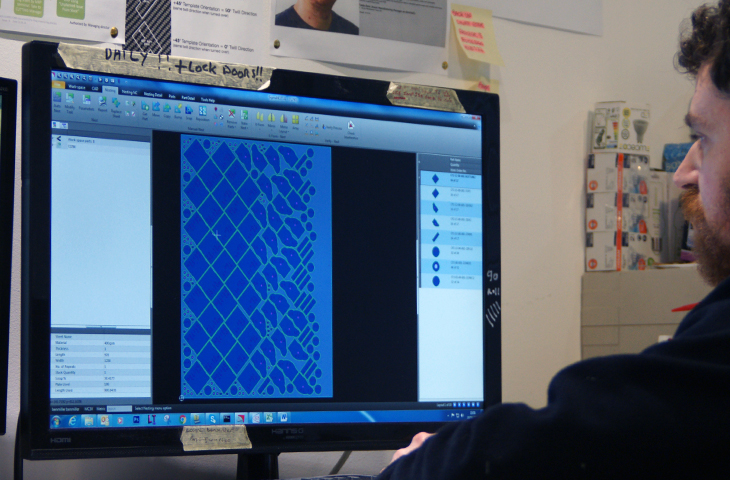

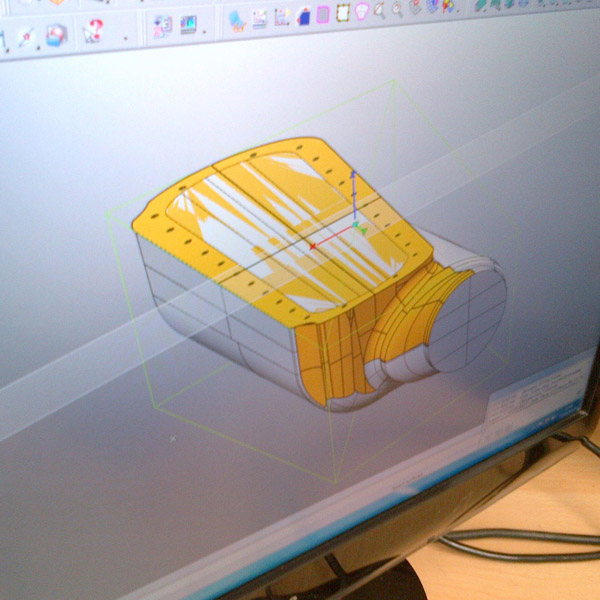

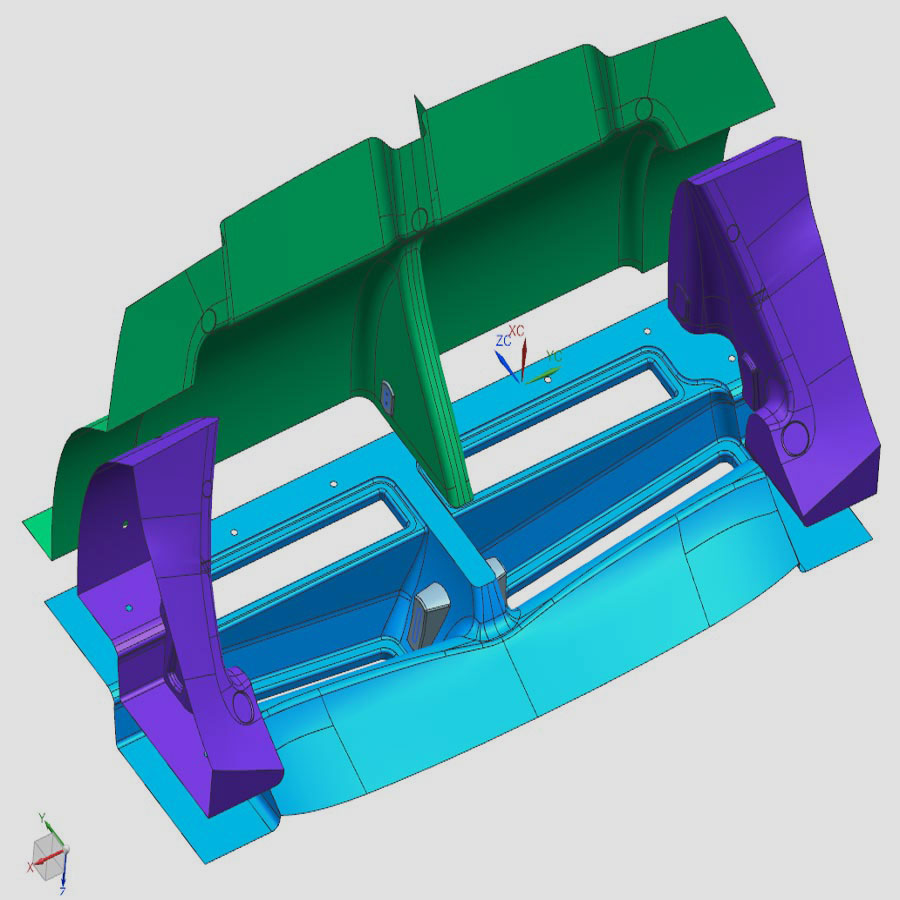

CAD Capabilities

We use Solidworks and hyperCAD-S software which allows us to undertake a wide range of design work digitally. The software allows us to provide conceptual images and helps aid in communicating the design process with the client. Both CAD software packages allow us to work on individual components or large assemblies.

We can use our 3D scanner or FARO arm for reverse engineering parts. Our FARO arm can also be used for inspection and confirming the manufacture of a part to tolerance.

We have a Vault file system that keeps all files secure and prevents overwriting which is a requirement of our ISO9001 accreditation.

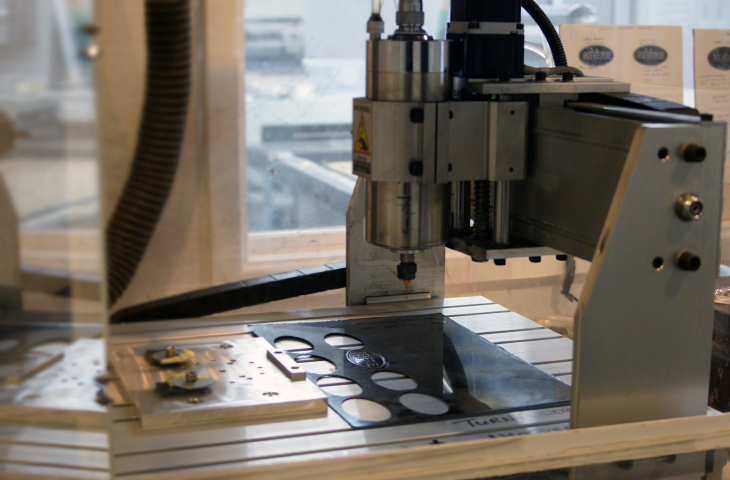

Prototyping

We can 3D print proof-of-concept or manufacture small one-off or short-run parts for prototyping purposes. We can print prototypes or functional models using our FDM printer with ABS filament or we can also provide SLS/SLA models which offer greater accuracy and surface finish. SLS/SLA printing is often used for production parts. We can machine epoxy tooling on-site with our HAAS 3-axis or Thermwood 5-axis CNC machines which is suitable for prototyping.