CNC Machining

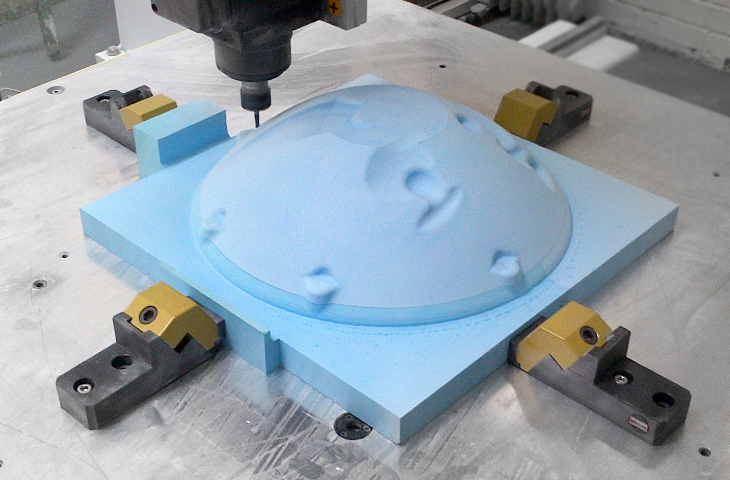

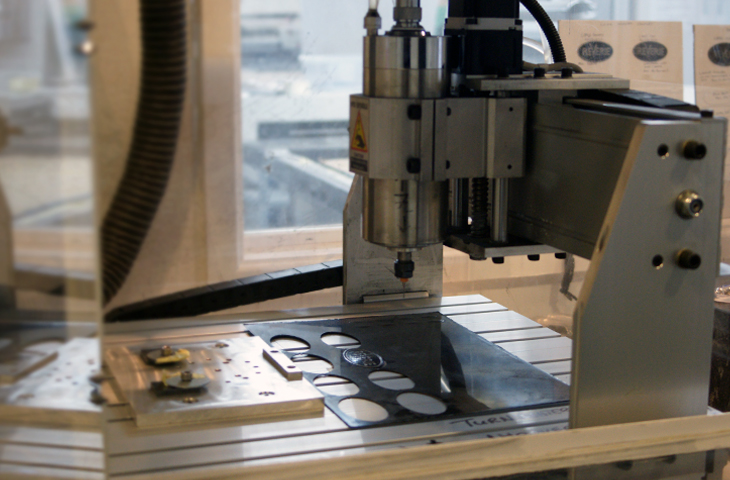

We can CNC machine composite parts (monolithic or sandwich boards) including carbon and glass fibre to precise measurements using our 3 and 5-axis CNC machines. We can also machine other materials such as wood and aluminium. We have two CNC machines plus a smaller engraving machine.

Our HAAS VF4 is fitted with a Reinsure OMP40 probe for accurate job setting and measuring of tool length. The HAAS VF4 is a 3-axis machine but can be converted to a 4-axis machine using our specially designed bed. Our Thermwood 5-axis CNC has a larger bed area than the HAAS VF4 and is suitable for machining multiple part nests.

We have various methods for mechanically or vacuum clamping components to the machine bed and can produce jigs and fixtures as required to ensure part stability during machining. We can inspect CNC machined components and produce 100% inspection reports using our FARO arm with CAM 2.0 software.

HAAS VF4 3+1-Axis

Max Area: 1270 x 508 x Z635mm (less machine tool length)

Accuracy: CFRP +/- 100microns, Alloy +/- 20microns

Motor: 30Hp 8100rpm spindle with BT40 taper.

Features: Reinsure OMP40 Probe for accurate job setting and tool length checking. Fitted with HRT310 4th axis and 910mm x 340mm T-Slot Bed on A-frame. Note; HAAS can be used for wet or dry cutting of alloy, steel and CFRP or Epoxy/Pu tooling blocks.

Thermwood M67-55 5-Axis Router

Max Area: 1524 x 1524 x Z914mm (less machine tool length)

Accuracy: +/- 150microns

Motor: 9KW 18,000rpm HSD with ISO30 taper.

Notes: Used for dry cuttting CFRP, Epoxy/PU tooling block and wood