Carbon Fibre Composite Manufacturing

Design, Engineering & Manufacture

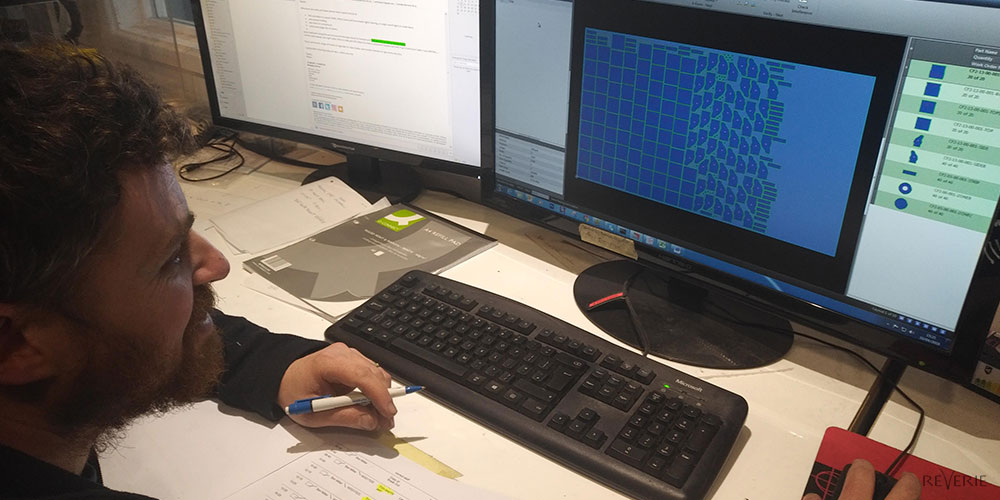

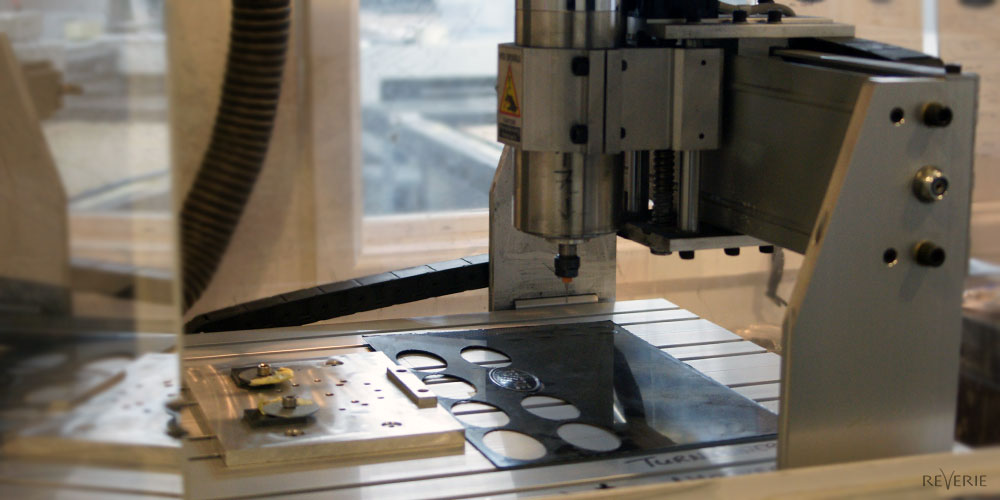

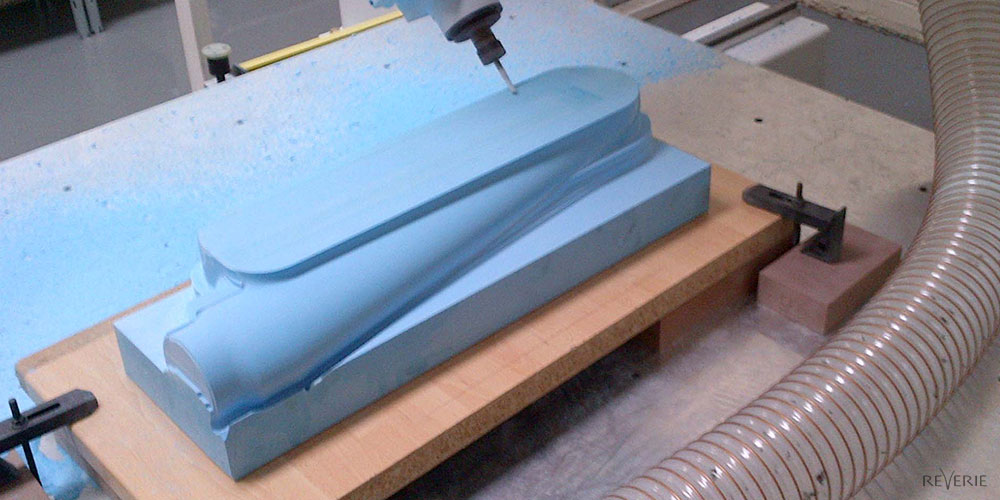

Reverie is acknowledged in the industry worldwide as being a highly accomplished and skilled carbon fibre composite design, repair and manufacturing company. We are an ISO9001 approved company* with over 19 years of experience crafting the finest polished or painted autoclaved Carbon Fibre pre-preg composite parts, from in-house CNC machined alloy or Carbon composite tooling.We can also manufacture genuine A-surface composite tooling for high volume manufacturing use.

We supply to the UK and export to overseas businesses and retail consumers with bespoke or batch produced, high quality, repeatable Carbon Fibre parts. We also offer a diverse range of Carbon composite parts for the electronics, communications, marine, home, construction and automotive markets. We can guarantee that through our extensive experience and autoclaving processes, tied in with our ability to machine alloy tools, alloy or epoxy patterns, or epoxy moulds or accurately trim composite parts using our 5 Axis CNC router, and Haas VF4. Checking of accuracy and quality using our FARO inspection arm or white light scanner, you will always be sure that you are receiving the highest quality carbon fibre goods and/or tools on the market.

Our Services:

- Composite tool design

- Composite part design

- Composite machining

- Composite bonding

- Carbon Fibre manufacture

- Pattern/tool CNC machining

- Carbon tool manufacture

- Pattern design

- Composite painting

- CNC pattern machining

- Composite repairs

- One-off/bespoke production

- Autoclaved composite pre-preg manufacture

- Large scale production

- Inspection and ISO9001

These are just a selection of the design and manufacturing services that we offer, view our services page or contact us to discuss your project with us.

Design, Manufacturing & Engineering Services Offered

Reverie has manufactured its own range of Lotus and universal automotive parts, as well as manufacturing small and large scale sub-contract parts for many industies. We offer many services to aid in manufacturing

Site Facilities

We also pride ourselves in having a workshop that can produce products from start to finish by machining our own moulds and tools, Machine kit cutting table, laminating clean rooms, trim shops, CNC machining and spray booth.

Companies We Have Worked With:

We pride ourselves in having our own branded parts used by companies all over the world. Our former and current clientele have included names such as, Bolin Webb, Cogent Technology, Quaife, Citroen Racing, AER, REGA, Cosworth Electronics, Funktion-One, M-Sport, Foggy PETRONAS, Gibson Technology, Openworks, Vislink and many more.

A few testimonials...

Gibson Technology

"Reverie limited has been selected by Gibson to be the sole composites manufacturer/supplier for the Engine Air box lower tray, Air box Mid-section and the LH and RH Coil covers. Reverie were selected due to proven supply, quality and quick response to technical queries on previous Gibson projects coupled with fair pricing and good upfront technical composites design for manufacture / tooling advice".

Dave James - Gibson Technology

Maple Group

"It was so pleasing to be able to just leave the car and come back a few weeks later to see that you had carried out the design and tooling as well as making and fitting the parts better than I could of imagined. What a breath of fresh air these days"

Alan Maple - Maple Group

Cosworth Electronics

“We are delighted with the support and service that we receive from Reverie in provision of moulded and cnc machined carbon fibre for our steering wheels, inc. CWW277 Mk1 and Mk2. We have been satisfied with the quality and efficiency of their work, which in turn has enabled us to maintain the high standards for which the Cosworth name is internationally renowned.”

Annys Kirk - Cosworth Electronics

- Download Document :: iso